First attempt at making punches

+5

hawcer

dartfreak75

Reload3006

Pathfinder

Daywalker

9 posters

Page 1 of 2

Page 1 of 2 • 1, 2

First attempt at making punches

First attempt at making punches

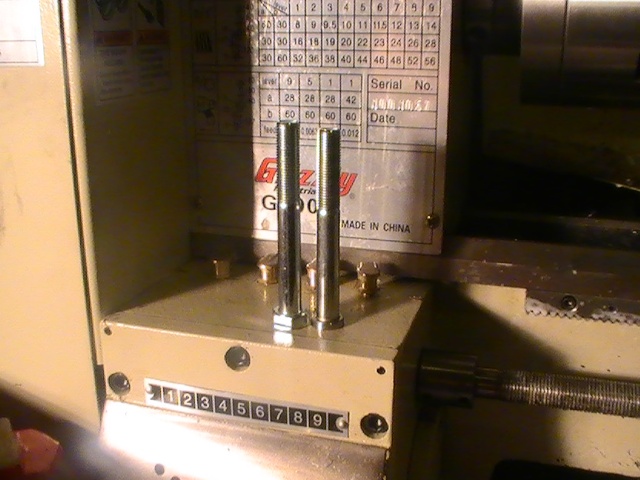

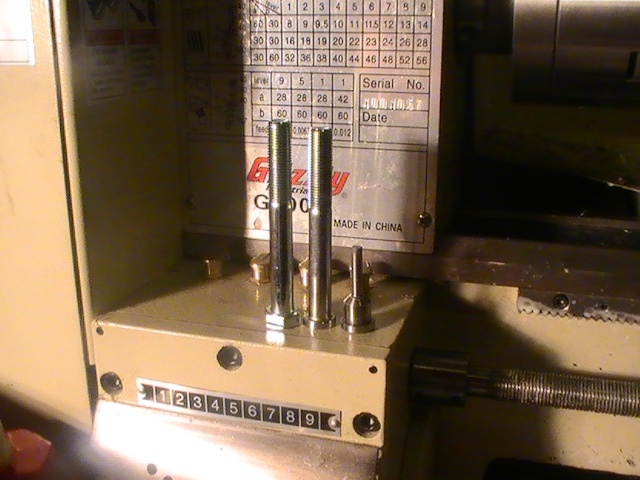

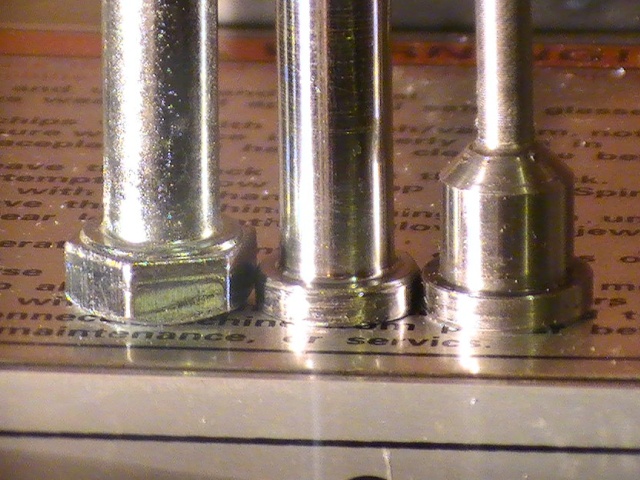

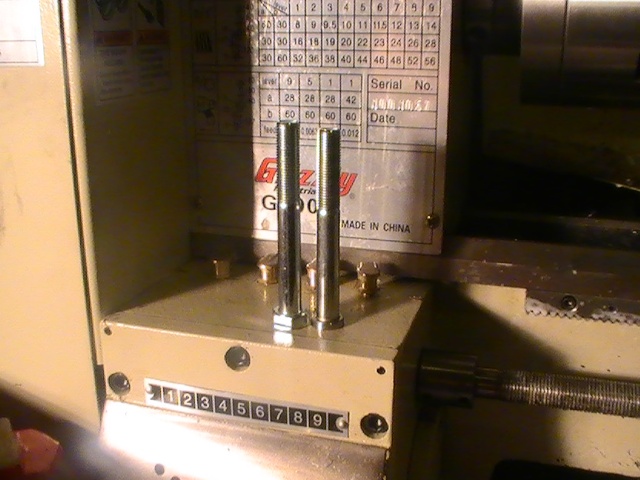

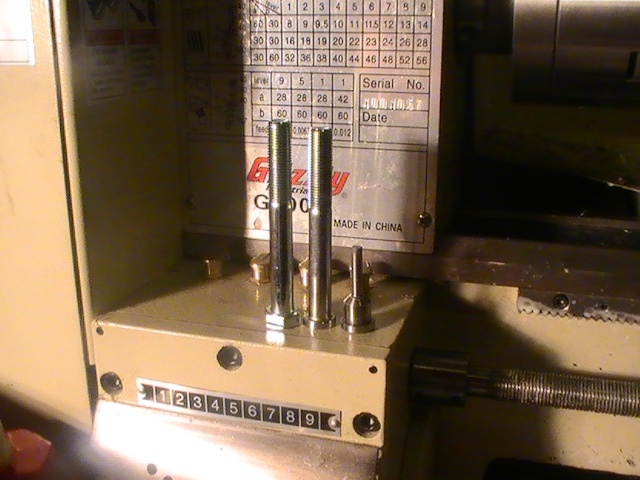

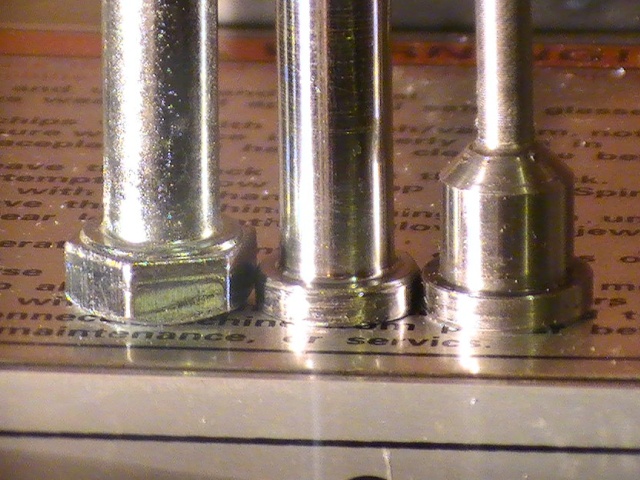

Well, maybe. The very firt attempt, the head of the bolt was so close to the diameter I needed that by the time I got it nice and round it wa too small. This attempt is the whole thing..... This will be the punch for the de rim die. The tip still needs to be brought down in size. It is at .200. Just below it is .198 and then ends up being like .195 towards the shoulder..... Also, as you can see, the punch is till yet a bit too long. I will be parting it off shorter and then reapplying the taper back to the tip...

I still have more polishing to do. I do have to say, not bragging or having a big head, however, I am pretty proud of myself!!! Never in a million years did I ever think I was going to own firearms, never in a million years did I think I would be reloading. I would have called you a liar if you had in the past told me people made bullets just by melting and pouring lead, and I now I am doing that as well, and I would have lost it if was ever told that a man could make his own jacket through a process called swaging...

Now, I am taking regular bolts and turning them into a die and punches!!! Lot of hard work pays off....

I still have more polishing to do. I do have to say, not bragging or having a big head, however, I am pretty proud of myself!!! Never in a million years did I ever think I was going to own firearms, never in a million years did I think I would be reloading. I would have called you a liar if you had in the past told me people made bullets just by melting and pouring lead, and I now I am doing that as well, and I would have lost it if was ever told that a man could make his own jacket through a process called swaging...

Now, I am taking regular bolts and turning them into a die and punches!!! Lot of hard work pays off....

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: First attempt at making punches

Re: First attempt at making punches

Looking good DW!

Pathfinder- Member

- Posts : 409

Join date : 2010-10-18

Age : 47

Location : WestWinfield New York

Re: First attempt at making punches

Re: First attempt at making punches

looking good DW My punches are .200 you are probably good to go now. Have you pushed any rim fires through yet?

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 64

Location : West Plains, Mo. , St. Louis ,Mo.

Re: First attempt at making punches

Re: First attempt at making punches

Thanks Pathfinder!!!

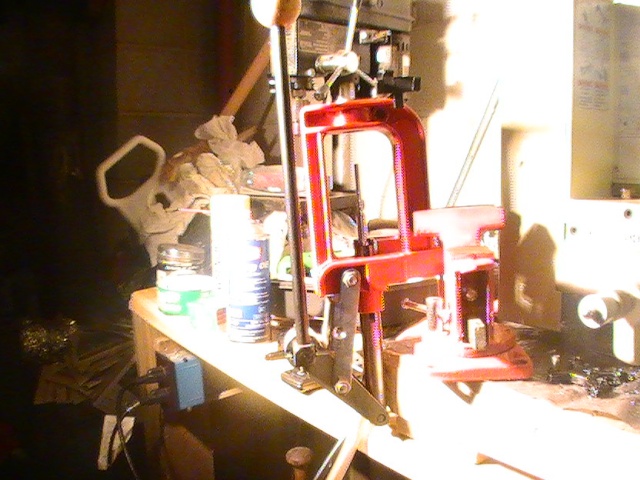

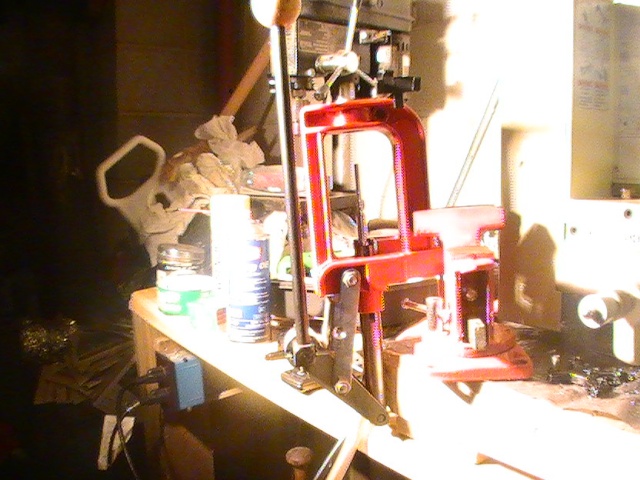

Reload3006, not yet. My de rim die is not finished. I am working on polishing the relief side of the die with what I have here. For the actual sizing portion, I sitll have it at .202. I am waiting on a reamer and a lap so that I can ream it to the final size and then use the lap to really give it that mirror finish. I don't want to mess this die up until I get those extra bit of tooling. What I am waiting on to be honest, I am trying to forsee how many laps I think I will need. I am not sure how quickly or how many dies I can get out of one Lap....

To everybody: LOL.....

An observation while making these. Number one, using the bolts is merely a way to practice. I don't mind making these for myself. Will I make more punches for me from bolt? No, reason...well how can I explain this. With a bolt, yes I can turn the head down and have it fit the ram great!! However, to work on the business end of things, have room for the tool to do it's job, The jaws of the chuck is claming against the head of the bolt only. Now there is not alot of bearing surface to hold onto. Using a dial indicator, It took me about 30 minutes just to get the bolt to where it turned without much wobble. Still had some, just not much. If you get into a bind, with such small bearing surface, it is easy to knock the work piece out of alignment in the lathe and then you got to shut down and again, take 30 minutes could even be an hour to get the work piece back true.

I piece of round stock will alow me to hold the work piece in steady and true a lot quicker!! I can start with turning the working end of the punch first and better then finish off with the section that goes into the ram..

I feel the second part will be the better route to go...I think I can get it it local without having to order bar stock I can't get locally... I think something like grade 5, which is what that bolt was, will be plenty enough to make the punch with.

Reload3006, not yet. My de rim die is not finished. I am working on polishing the relief side of the die with what I have here. For the actual sizing portion, I sitll have it at .202. I am waiting on a reamer and a lap so that I can ream it to the final size and then use the lap to really give it that mirror finish. I don't want to mess this die up until I get those extra bit of tooling. What I am waiting on to be honest, I am trying to forsee how many laps I think I will need. I am not sure how quickly or how many dies I can get out of one Lap....

To everybody: LOL.....

An observation while making these. Number one, using the bolts is merely a way to practice. I don't mind making these for myself. Will I make more punches for me from bolt? No, reason...well how can I explain this. With a bolt, yes I can turn the head down and have it fit the ram great!! However, to work on the business end of things, have room for the tool to do it's job, The jaws of the chuck is claming against the head of the bolt only. Now there is not alot of bearing surface to hold onto. Using a dial indicator, It took me about 30 minutes just to get the bolt to where it turned without much wobble. Still had some, just not much. If you get into a bind, with such small bearing surface, it is easy to knock the work piece out of alignment in the lathe and then you got to shut down and again, take 30 minutes could even be an hour to get the work piece back true.

I piece of round stock will alow me to hold the work piece in steady and true a lot quicker!! I can start with turning the working end of the punch first and better then finish off with the section that goes into the ram..

I feel the second part will be the better route to go...I think I can get it it local without having to order bar stock I can't get locally... I think something like grade 5, which is what that bolt was, will be plenty enough to make the punch with.

Last edited by Daywalker on Thu Jan 06, 2011 9:20 am; edited 1 time in total

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: First attempt at making punches

Re: First attempt at making punches

awsome job man looks great cant wait to get one off ya!!

dartfreak75- Member

- Posts : 1182

Join date : 2010-11-21

Age : 39

Location : southwest va

Re: First attempt at making punches

Re: First attempt at making punches

Thanks...This one still has some tool chatter that I am trying to buff out. I just don't want to take any more material off the punch. I am going to sharpen my turning tool today so hopefully that will do away with some of that...

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: First attempt at making punches

Re: First attempt at making punches

looking real snazzy....keep it up!

hawcer- Mod

- Posts : 1896

Join date : 2010-11-04

Age : 52

Re: First attempt at making punches

Re: First attempt at making punches

a little trick for ya on long small pieces use a very pointy tool it will help with the chatter. also if you center drill the bolt and run your live center while turning it will help. if i were using a bolt to turn i would use my 3 jaw chuck and chuck on the hex of the bolt then indicate the outer end as true as i could get it center drill it and push my tail stock with a live center into it it will make it pretty solid for turning. then you can face the center hole out if you dont want it.

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 64

Location : West Plains, Mo. , St. Louis ,Mo.

Re: First attempt at making punches

Re: First attempt at making punches

Yea, I still have my 3 jaw set up for now. For the most part, I did use my live center to stabalize it. There were times tho, that I had to move the tailstock back as I could not work with the end of the bolt. Or at least learned how to work around it yet LOL....

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: First attempt at making punches

Re: First attempt at making punches

DW, try this...

Useing your second method, start with a rod that is the OD of the seat diameter of your ram. Turn down the working end of the punch, then use a parting cutter and simply cut off the finished punch from the rod.. DUN!

This way you dont have to turn the work around...lol

Useing your second method, start with a rod that is the OD of the seat diameter of your ram. Turn down the working end of the punch, then use a parting cutter and simply cut off the finished punch from the rod.. DUN!

This way you dont have to turn the work around...lol

xboxhacker- Posts : 17

Join date : 2010-12-21

Re: First attempt at making punches

Re: First attempt at making punches

Yea I have a parting tool. It works really great!!

The reason why I would start out with a rod that is larger in diameter, is so that I could turn it down while cleaning the rod up and trueing it as I go. I would love to get the exact diameter, which is .555 for the ram, however, they would have to sell it machined and perfectly round. I am not even sure if they sell rod stock that is .555, I believe the closest one, and it is the one I am getting is 5/8 bar stock and that is around .625 round bouts. Not much turning, but just enough to clean it up.

Then again, I may be totally wrong with my thinking?? What you think??

The reason why I would start out with a rod that is larger in diameter, is so that I could turn it down while cleaning the rod up and trueing it as I go. I would love to get the exact diameter, which is .555 for the ram, however, they would have to sell it machined and perfectly round. I am not even sure if they sell rod stock that is .555, I believe the closest one, and it is the one I am getting is 5/8 bar stock and that is around .625 round bouts. Not much turning, but just enough to clean it up.

Then again, I may be totally wrong with my thinking?? What you think??

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: First attempt at making punches

Re: First attempt at making punches

as long as you have some thing for your t-slot on your ram to hang on to i wouldn't think it would have to be that close because all the pressure that will be on it is pulling the punch back out of the finished jacket. fact you could even leave it hex. if it can float a little it will align with the hole in your die easier.

but you would want to face the end so its square with the axis of the punch.

but you would want to face the end so its square with the axis of the punch.

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 64

Location : West Plains, Mo. , St. Louis ,Mo.

Re: First attempt at making punches

Re: First attempt at making punches

Some very good valid points!!! Never thought about that...

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: First attempt at making punches

Re: First attempt at making punches

Daywalker try using SOCKET HEAD cap screws much harder and tougher. Won't wear out ad fast. More later after work.

Jim_Fleming- Posts : 14

Join date : 2010-11-17

Re: First attempt at making punches

Re: First attempt at making punches

Daywalker wrote:Yea I have a parting tool. It works really great!!

The reason why I would start out with a rod that is larger in diameter, is so that I could turn it down while cleaning the rod up and trueing it as I go. I would love to get the exact diameter, which is .555 for the ram, however, they would have to sell it machined and perfectly round. I am not even sure if they sell rod stock that is .555, I believe the closest one, and it is the one I am getting is 5/8 bar stock and that is around .625 round bouts. Not much turning, but just enough to clean it up.

Then again, I may be totally wrong with my thinking?? What you think??

Use the 5/8 stock. Just turn down the working end, then turn down the lip for the seat (.555)... then use parting tool to part it off....

like this....

xboxhacker- Posts : 17

Join date : 2010-12-21

Re: First attempt at making punches

Re: First attempt at making punches

xboxhacker, you scare me what you can do on the internet.......

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: First attempt at making punches

Re: First attempt at making punches

LOLOLOL!!!!!!

I get bored VERY easy!!

I get bored VERY easy!!

Last edited by xboxhacker on Thu Jan 06, 2011 2:01 pm; edited 1 time in total

xboxhacker- Posts : 17

Join date : 2010-12-21

Re: First attempt at making punches

Re: First attempt at making punches

But yea, that is what I have in mind. I just have to go get some bar stock to give it go. I just wish it was as easy as that pic. I really have to look into getting cnc hook up for my lathe. The stuff for the lathe isn't that bad. I can get it and hook it up. The software is what is going to cost nd then on top of that, trying to learn to read the software and learn it. That in itself is what stops me from doing that...

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: First attempt at making punches

Re: First attempt at making punches

actually Day NC IMO is a lot easier than conventional. I have been doing that for years Most newer controls have a conversational programing function built in. and it is a lot easier. On every caliber but maybe the 22 you could bore your point form die too. And your right Graphics cut a lot easier than Steel in my experience.

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 64

Location : West Plains, Mo. , St. Louis ,Mo.

Re: First attempt at making punches

Re: First attempt at making punches

Daywalker wrote:But yea, that is what I have in mind. I just have to go get some bar stock to give it go. I just wish it was as easy as that pic. I really have to look into getting cnc hook up for my lathe. The stuff for the lathe isn't that bad. I can get it and hook it up. The software is what is going to cost nd then on top of that, trying to learn to read the software and learn it. That in itself is what stops me from doing that...

NO, use Mach3 for CNC control its SOOOOO EASY (+/- FREE)!!!! Trust me, dont let it scare you. I use Mach3 for a CNC engraver i made to make PCBs, for my electronic projects...

All the cost is in the stepper driver board, motors and a control computer (older the better)

Now, a little off topic, if you liked that animation above, look at my latest project:

Bend Calculator <~~link

xboxhacker- Posts : 17

Join date : 2010-12-21

Re: First attempt at making punches

Re: First attempt at making punches

Wow, interesting project....

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: First attempt at making punches

Re: First attempt at making punches

Reload3006 wrote:And your right Graphics cut a lot easier than Steel in my experience.

It always is

But i spent 8 years working in a machine shop....steel isn't that bad

I would kill for a lathe and a mill....not even a good one, just cheap! But i am flat broke, wife has no job, 2 kids, house in foreclosure..... witch brings me to this site, i have to feed my AR15, so it has to be cheap... so reloading seems like a good choice.

Last edited by xboxhacker on Thu Jan 06, 2011 2:17 pm; edited 1 time in total

xboxhacker- Posts : 17

Join date : 2010-12-21

Re: First attempt at making punches

Re: First attempt at making punches

yea im working on 35 yrs in a machine shop

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 64

Location : West Plains, Mo. , St. Louis ,Mo.

Re: First attempt at making punches

Re: First attempt at making punches

xboxhacker = jack of all trades, master of none.

xboxhacker- Posts : 17

Join date : 2010-12-21

Re: First attempt at making punches

Re: First attempt at making punches

DW looken great

johndeereboy24- Posts : 33

Join date : 2011-01-02

Age : 43

Location : SE kansas

Page 1 of 2 • 1, 2

Similar topics

Similar topics» new to casting making a start

» Making ur own lead shot

» making my own overshot cards...

» Making Copper Tubing Jacketed .357 bullets

» Making Jacketed Hollow Point .45 acp Bullets Using A Lee .243 Sizing And .40 S&W Bras

» Making ur own lead shot

» making my own overshot cards...

» Making Copper Tubing Jacketed .357 bullets

» Making Jacketed Hollow Point .45 acp Bullets Using A Lee .243 Sizing And .40 S&W Bras

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum|

|

|