Core seating Die

3 posters

Page 1 of 1

Core seating Die

Core seating Die

well guys.. more and more, as i thought about it, i decided to make a core seating die and punch.

took a bolt and chucked it up in my drill, and used my bench grinder to get it close to how i wanted it.

then i chucked it up in my drill press, and worked it with some files and sand paper until it was exactly how i wanted it.

next, i cut it free with a band saw, and cleaned the cut on the top, then finished the lead bleed hole through to the base.

next, i took one of my die bolts with a pilot hole of .210 then cut a .224 hole through 2/3 of the way through. took a cold rolled steel bar, and turned it until it was .209 and left the base of it at .223. i tapped the end with some threads, then assembled it into the die to become the ejector punch.

the ejector punch base supports the entire bottom of the cup, so that i dont deform it while pressing lead into it.

now i just have to make a core mold to make me some core's to seat!! i'll update you all on its progress.. i'll be working on that today. with any luck the steel yard will have some scrap aluminum for me to use as a mold.

thanks,

Dan

took a bolt and chucked it up in my drill, and used my bench grinder to get it close to how i wanted it.

then i chucked it up in my drill press, and worked it with some files and sand paper until it was exactly how i wanted it.

next, i cut it free with a band saw, and cleaned the cut on the top, then finished the lead bleed hole through to the base.

next, i took one of my die bolts with a pilot hole of .210 then cut a .224 hole through 2/3 of the way through. took a cold rolled steel bar, and turned it until it was .209 and left the base of it at .223. i tapped the end with some threads, then assembled it into the die to become the ejector punch.

the ejector punch base supports the entire bottom of the cup, so that i dont deform it while pressing lead into it.

now i just have to make a core mold to make me some core's to seat!! i'll update you all on its progress.. i'll be working on that today. with any luck the steel yard will have some scrap aluminum for me to use as a mold.

thanks,

Dan

DanRickard- Member

- Posts : 207

Join date : 2010-10-18

Age : 50

Location : vancouver, wa

Re: Core seating Die

Re: Core seating Die

Looking good! Are you gonna heat treat it to make it a little harder so it has less chance of smushing over?

hawcer- Mod

- Posts : 1896

Join date : 2010-11-04

Age : 52

Re: Core seating Die

Re: Core seating Die

hawcer wrote:Looking good! Are you gonna heat treat it to make it a little harder so it has less chance of smushing over?

naw.. both the punch bolt i used and the die bolt are #8 tempered already.. so no need..

DanRickard- Member

- Posts : 207

Join date : 2010-10-18

Age : 50

Location : vancouver, wa

Re: Core seating Die

Re: Core seating Die

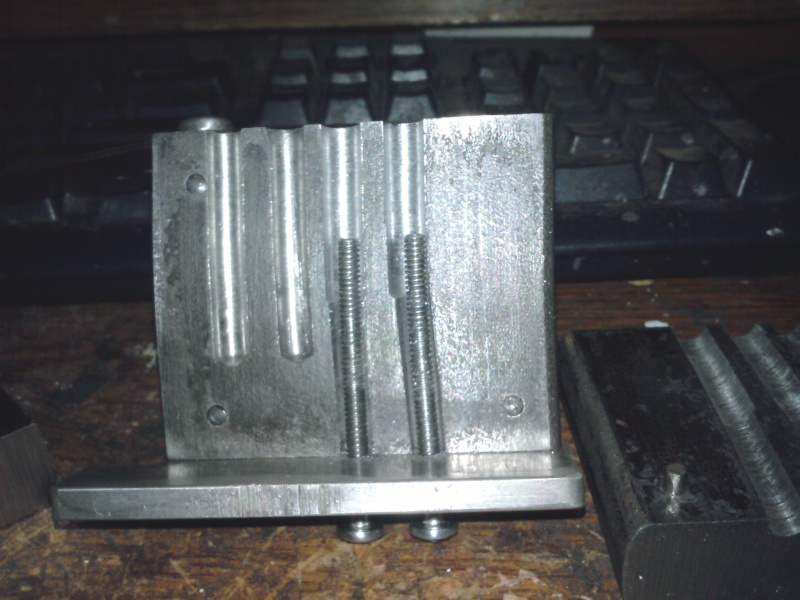

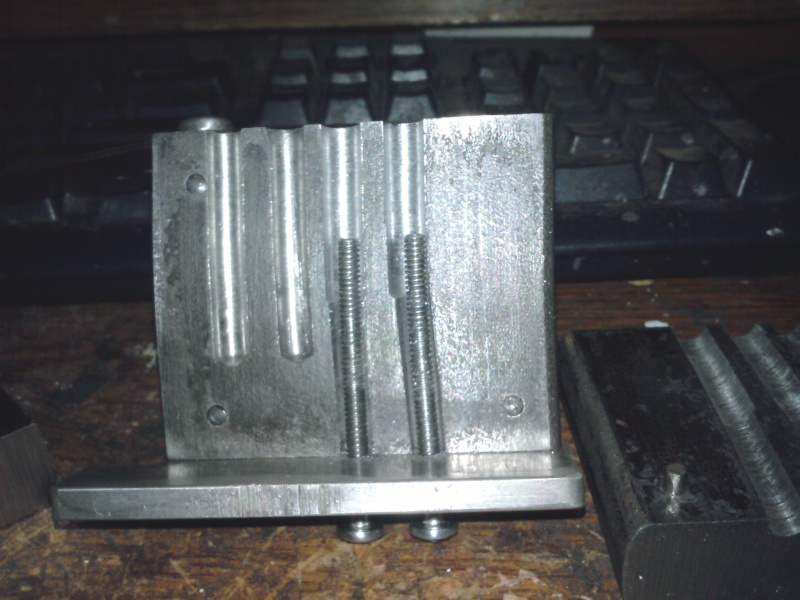

well, i ended up making a combination mold once i noticed my drill press was wondering off to one side.. i was bummed.. but made the best of it.

now, i have a steel mold that can cast 2 cores, which are long enough to make 4 bullets. then 2 cavities to hot pour lead directly into the cups.

all along, i've always been doing a hot pour into my cups, and it works out pretty well.. my current mold for doing this, is only a single cavity, so its kind of nice having a dual cavity mold to do the same thing. the two screws at the bottom adjusts where the cup sits in the mold, so that i can bring the cups up against the spur plate.

here are the pics..

now i just have to make some handles..

thanks,

dan

now, i have a steel mold that can cast 2 cores, which are long enough to make 4 bullets. then 2 cavities to hot pour lead directly into the cups.

all along, i've always been doing a hot pour into my cups, and it works out pretty well.. my current mold for doing this, is only a single cavity, so its kind of nice having a dual cavity mold to do the same thing. the two screws at the bottom adjusts where the cup sits in the mold, so that i can bring the cups up against the spur plate.

here are the pics..

now i just have to make some handles..

thanks,

dan

DanRickard- Member

- Posts : 207

Join date : 2010-10-18

Age : 50

Location : vancouver, wa

DanRickard- Member

- Posts : 207

Join date : 2010-10-18

Age : 50

Location : vancouver, wa

Re: Core seating Die

Re: Core seating Die

but i gotta say, the next time i make a mold, it will be out of aluminum.. the steel makes a heavy f'ing mold guys..

its nice to have steel, cause its more durable.. and well, kinda easy to work with.. but the weight of it, is well.. horrible.

we'll see how it casts in a little while.

thanks,

dan

its nice to have steel, cause its more durable.. and well, kinda easy to work with.. but the weight of it, is well.. horrible.

we'll see how it casts in a little while.

thanks,

dan

DanRickard- Member

- Posts : 207

Join date : 2010-10-18

Age : 50

Location : vancouver, wa

Re: Core seating Die

Re: Core seating Die

very nice!!!

kcatto- Member

- Posts : 648

Join date : 2010-11-15

Age : 52

Location : Oklahoma

Similar topics

Similar topics» Core Seating Punch

» .45 ACP 185 gr Speer Hot Core HP

» My Pro1000 isn't seating my bullets straight?

» .223 Remington Bullet Seating Depth vs. Pressure

» Success with my adjustable core molds.

» .45 ACP 185 gr Speer Hot Core HP

» My Pro1000 isn't seating my bullets straight?

» .223 Remington Bullet Seating Depth vs. Pressure

» Success with my adjustable core molds.

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|