Home made 22lr to 223 bullets

+3

kcatto

Daywalker

eagle60

7 posters

Page 1 of 1

Home made 22lr to 223 bullets

Home made 22lr to 223 bullets

I can in no way afford the dies that turns 22lr cases into .223 bullets so I wanted to try my luck at making the dies and a press heavy enough to handle the pressure. The upside is that I was able to accomplish that, and they were safe enough that I didn't have any unexpected surprises. Keep in mind that my approach was pretty much unconventional to say the least, but was more of a "just to see if I can do it" sort of thing. Admittedly, they are not too pretty and the performance - as expected - sucked!! But, I can say that I was able to load and shoot some bullets that I made. So here are some pics of what you may (not) want to try at home

Dies were made out of cold roll steel that a friend donated to the cause. No kind of heat treatment was attempted. They were made on the small harbor freight 7x12 lathe.

They were loaded into LC97 cases over a light load of 24 grains H335 and cci 400 primers. OAL was 2.200.

They were fired in a Del-Ton Industries AR-15, 16 inch bbl, 1x7 twist. Target was at 50 yards.

So here's the deal - I post these so ya'll can have a good chuckle, but in return I'm looking for tips and tricks that may improve the end result. (I know, the store bought dies would fix it, please refer to sentence number 1 )

)

Dies

Bullets and Cases

Final Weight

Loaded rounds

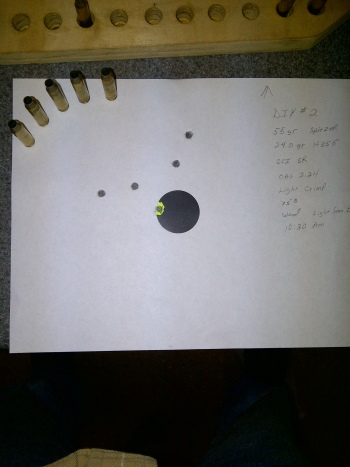

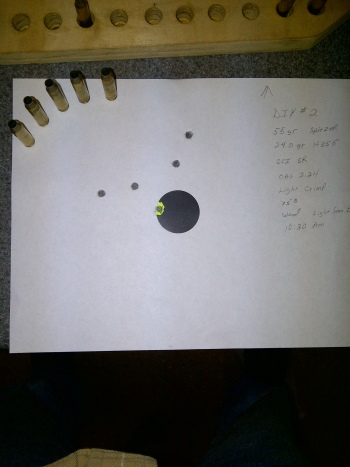

Five shot group - The first shot made was the one that hit the bullseye, and I'm thinking it is gonna be a good day!! It went south from there LOL! The last shot was off the paper to the lower left. Yep, a 6.25 inch group at 50 yards.... if you don't count the one that was off the paper LOL!

All in all I guess they turned out ok for trial and error but I definately want to improve the performance if possible. Suggestions anyone ?

Dies were made out of cold roll steel that a friend donated to the cause. No kind of heat treatment was attempted. They were made on the small harbor freight 7x12 lathe.

They were loaded into LC97 cases over a light load of 24 grains H335 and cci 400 primers. OAL was 2.200.

They were fired in a Del-Ton Industries AR-15, 16 inch bbl, 1x7 twist. Target was at 50 yards.

So here's the deal - I post these so ya'll can have a good chuckle, but in return I'm looking for tips and tricks that may improve the end result. (I know, the store bought dies would fix it, please refer to sentence number 1

Dies

Bullets and Cases

Final Weight

Loaded rounds

Five shot group - The first shot made was the one that hit the bullseye, and I'm thinking it is gonna be a good day!! It went south from there LOL! The last shot was off the paper to the lower left. Yep, a 6.25 inch group at 50 yards.... if you don't count the one that was off the paper LOL!

All in all I guess they turned out ok for trial and error but I definately want to improve the performance if possible. Suggestions anyone ?

Last edited by Daywalker on Sun Aug 14, 2011 9:30 pm; edited 1 time in total (Reason for editing : deleted photo url link)

eagle60- Member

- Posts : 971

Join date : 2011-01-02

Location : East Central MS

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

You have a very good start it appears. From nothing to shooting down range is definatly not a failure.

What sizes is your case once you de rim them?

What size is your core after you swage your core with the squirt die?

What size if your seated core in the case?

What is the final size of the Pill after it is ejected from the point forming die?

Not really sure I can help you persay, I am by no means an expert, heck I would not even consider myself a hobbiest at this point but working on it.

Maybe together, we can all work through it.....

I say very great job for going from nothing to something with what you got..

With the prices of bullets now and days, I forsee the day when swaging will come as second nature as loading. Bullet Casting has already rose above and paper patching is making a come back.

Very soon, it will be very common to read about swaging.......

What sizes is your case once you de rim them?

What size is your core after you swage your core with the squirt die?

What size if your seated core in the case?

What is the final size of the Pill after it is ejected from the point forming die?

Not really sure I can help you persay, I am by no means an expert, heck I would not even consider myself a hobbiest at this point but working on it.

Maybe together, we can all work through it.....

I say very great job for going from nothing to something with what you got..

With the prices of bullets now and days, I forsee the day when swaging will come as second nature as loading. Bullet Casting has already rose above and paper patching is making a come back.

Very soon, it will be very common to read about swaging.......

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

I agree from nothing to something is often the hardest battle...

very well done.... remember 6.25 inch at 50 yards is still in the kill zone for deer.... so not complete failure....

very well done.... remember 6.25 inch at 50 yards is still in the kill zone for deer.... so not complete failure....

kcatto- Member

- Posts : 648

Join date : 2010-11-15

Age : 52

Location : Oklahoma

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Eagle my hat is off to you A little tweaking and you will be in business. Congrats

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 65

Location : West Plains, Mo. , St. Louis ,Mo.

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Great job man....when push comes to shove, those home made bullets could be worth their weight in gold. Keep working at it...

Just remember, any little wobble will throw the bullets of course. The point is the easiest way to cause or correct this. Chuck one up in a drill....if the point has a lot of wobble, you might be better off with no point at all or try to even up and center the point to remove the wobble.

Just remember, any little wobble will throw the bullets of course. The point is the easiest way to cause or correct this. Chuck one up in a drill....if the point has a lot of wobble, you might be better off with no point at all or try to even up and center the point to remove the wobble.

hawcer- Mod

- Posts : 1896

Join date : 2010-11-04

Age : 53

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Thanks guys. I have found a couple of things that is working against me. Hawcer, I did as you suggested and chucked it up in the lathe. There is runout at the point, not so much on the ogive as the lead tip. My idea is to make "holder" that fits the ram so as to encase most of the bullet when I straighten up the tip after forming the point. I don't have an ejection system in the ram (yet) so punching them out of the dies may be contributing to the problem. The other thing is the punch that I am using is a little undersized and is pressing more on one side than the other when doing the final sizing back to .224. It leaves a small cupped place to one side which may be contributing to the yaw effect, so I can see another punch in the future.

Another thing that I can't figure out is why the walls of the bullet (bearing surface) is wrinkling up. It's pretty bad until I do the final size on them which I presume irons some of that out. Die not polished enough maybe?

I guess I should add that I anneal one third of the case before seating the core. Makes it easier to do the point forming operation.

Thanks Reload! Coming from a seasoned machinest such as yourself, I am honored.

Thanks kcatto. I'll settle for deer sized targets for now but someday, I'd like to use mice for targets lol!

Daywalker, Thanks for cleaning up the pics for me. To answer your questions;

Derimmed 22lr cases

Swaged Core

Seated Core

Final Size

I made a couple of 62gr out of some nickel plated cases just for grins. Look pretty slick other than having the runout.

Another thing that I can't figure out is why the walls of the bullet (bearing surface) is wrinkling up. It's pretty bad until I do the final size on them which I presume irons some of that out. Die not polished enough maybe?

I guess I should add that I anneal one third of the case before seating the core. Makes it easier to do the point forming operation.

Thanks Reload! Coming from a seasoned machinest such as yourself, I am honored.

Thanks kcatto. I'll settle for deer sized targets for now but someday, I'd like to use mice for targets lol!

Daywalker, Thanks for cleaning up the pics for me. To answer your questions;

Derimmed 22lr cases

Swaged Core

Seated Core

Final Size

I made a couple of 62gr out of some nickel plated cases just for grins. Look pretty slick other than having the runout.

eagle60- Member

- Posts : 971

Join date : 2011-01-02

Location : East Central MS

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Would you be able to bump that up an extra thousand to make it .224? That may help it engage the riflings better and stabalize it. Then again, I am not sure of your bore size. Were you getting any key holeing?

Daywalker- Admin

- Posts : 2324

Join date : 2010-10-18

Location : Virginia

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

May be able to polish out the extra .001. I used a .223 reamer for the final sizing die and did a good deal of polishing on it. I measured some of the bulk bullets that I had bought a while back and they measured .222. I may slug the barrel to see exactly size I'm working with.

No keyholing - they all went straight through that 1/8 inch steel door that the target was taped to. I didn't run those through the chrony so I'm not sure what the velocity was. I was a full grain less on the powder than I normally use for factory bullets. That may have had some to do with it I guess. It may be a case of several small things adding up rather than one major problem.

No keyholing - they all went straight through that 1/8 inch steel door that the target was taped to. I didn't run those through the chrony so I'm not sure what the velocity was. I was a full grain less on the powder than I normally use for factory bullets. That may have had some to do with it I guess. It may be a case of several small things adding up rather than one major problem.

eagle60- Member

- Posts : 971

Join date : 2011-01-02

Location : East Central MS

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

WOW Eagle. Thats awesome. Nice work brother.

Pathfinder- Member

- Posts : 409

Join date : 2010-10-18

Age : 48

Location : WestWinfield New York

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Thanks Pathfinder!

eagle60- Member

- Posts : 971

Join date : 2011-01-02

Location : East Central MS

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Great job on the home made dies KUDOS!!!!!

I see a couple of things that could have been hurting your accuracy. you should be .224 but honestly a .001 isn't really going to hurt you that bad. I see in your picture that the point is folded back on its self or just looks that way. You can help that by ) Did you anneal the brass after you derimed it?

you will really help yourself if you anneal them. also its better to leave them a little long and on the lead tip you may want to trim that off at 5000+ RPM that can throw you every where kinda like a gyroscope.

I see a couple of things that could have been hurting your accuracy. you should be .224 but honestly a .001 isn't really going to hurt you that bad. I see in your picture that the point is folded back on its self or just looks that way. You can help that by ) Did you anneal the brass after you derimed it?

you will really help yourself if you anneal them. also its better to leave them a little long and on the lead tip you may want to trim that off at 5000+ RPM that can throw you every where kinda like a gyroscope.

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 65

Location : West Plains, Mo. , St. Louis ,Mo.

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Thanks for all the suggestions guys!

The subject of wobble has been mentioned a couple of times and that is the area that I will work on first. So, I plan on decreasing or eliminating the wobble toward the tip by shortning the length of protruding lead at the point or remaking the point forming die if I have to. I am going to make another punch for the final sizing operation so that the base of the bullet is good and flat and square to the sides.

The core seating punch that I used on these has somewhat of a tapered hole in the end so that when I seat the lead it also forms a cone shape on the lead. I'm thinking that if the case doesn't form uniformly around that cone it is gonna give me some wobble at the tip. I'm going to try using the normal cylinder of lead and let the point forming die form it as it needs to. (Shouldn't be much of a task for that monstrosity of a press lol )

I did anneal the brass after derimming, yes sir, that makes a big difference.

I guess that is why they call this the research and developement phase - I do a lot of research and develope a lot of headaches lol!!

I will keep ya'll updated on the progress as I can. Seems like "Me" time is harder to come by nowdays

Thanks again folks, you have been a great help.

The subject of wobble has been mentioned a couple of times and that is the area that I will work on first. So, I plan on decreasing or eliminating the wobble toward the tip by shortning the length of protruding lead at the point or remaking the point forming die if I have to. I am going to make another punch for the final sizing operation so that the base of the bullet is good and flat and square to the sides.

The core seating punch that I used on these has somewhat of a tapered hole in the end so that when I seat the lead it also forms a cone shape on the lead. I'm thinking that if the case doesn't form uniformly around that cone it is gonna give me some wobble at the tip. I'm going to try using the normal cylinder of lead and let the point forming die form it as it needs to. (Shouldn't be much of a task for that monstrosity of a press lol )

I did anneal the brass after derimming, yes sir, that makes a big difference.

I guess that is why they call this the research and developement phase - I do a lot of research and develope a lot of headaches lol!!

I will keep ya'll updated on the progress as I can. Seems like "Me" time is harder to come by nowdays

Thanks again folks, you have been a great help.

eagle60- Member

- Posts : 971

Join date : 2011-01-02

Location : East Central MS

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

one other thing I noticed. and this could be hurting your accuracy more than the bullets you made. You said the rifle you used was a 1:7 twist Man that is a fast twist and you should be shooting from 65 to 70+ grainers in that. My Savage 12 with a 1:9 twist will not shoot anything lighter than a 62. My targets look just like yours when I try to shoot 55 grain store bought bullets out of that rifle.

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 65

Location : West Plains, Mo. , St. Louis ,Mo.

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Reload3006 wrote:one other thing I noticed. and this could be hurting your accuracy more than the bullets you made. You said the rifle you used was a 1:7 twist Man that is a fast twist and you should be shooting from 65 to 70+ grainers in that. My Savage 12 with a 1:9 twist will not shoot anything lighter than a 62. My targets look just like yours when I try to shoot 55 grain store bought bullets out of that rifle.

+1 on this i did not even catch this....

kcatto- Member

- Posts : 648

Join date : 2010-11-15

Age : 52

Location : Oklahoma

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

It looks like I would have learned this by now----

Ok, I have some store bought 62gr and 55gr loaded up. I can compare the results of the two, then make some home made ones based on the results of that test. If the heavier home built bullets give better performance ,and I'm thinking they will, I should be able to fine tune from there.

Nice catch Reload!!!

Ok, I have some store bought 62gr and 55gr loaded up. I can compare the results of the two, then make some home made ones based on the results of that test. If the heavier home built bullets give better performance ,and I'm thinking they will, I should be able to fine tune from there.

Nice catch Reload!!!

eagle60- Member

- Posts : 971

Join date : 2011-01-02

Location : East Central MS

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

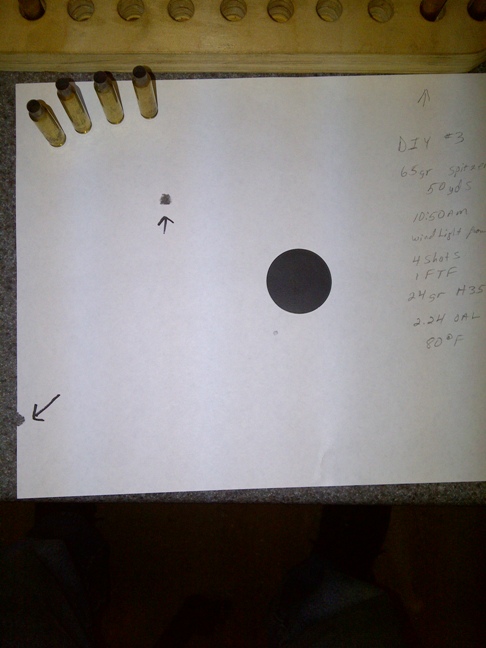

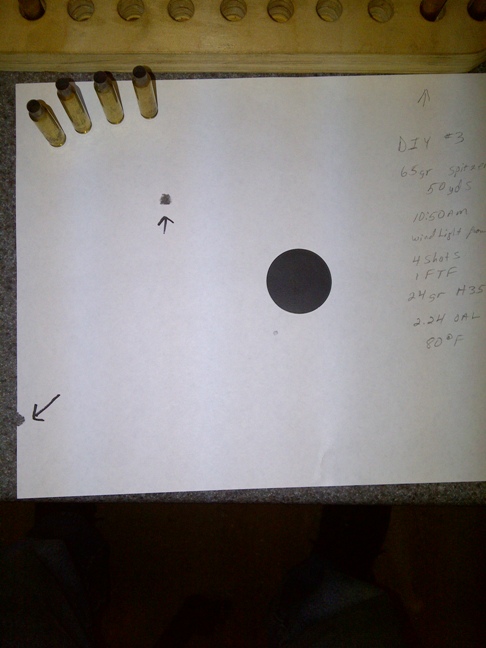

UPDATE::

I have added pics for these--

Since my last post I added a riser to the DTI flat top. I made a new point forming die, a new punch for the final sizing die, and polished out the final sizing die to .224. Made up some 55 grainers without lead tips and some 65 grainers without lead tips. The runout at the tip was all but eliminated so I went ahead and loaded up 5 each over the same charge of 24gr of H355.

Got out this morning and sighted in the scope again using factory 55 gr hp ammo which resulted in a 1 inch group. Not exceptional but these progressive lens im my glasses give me hell. I have not done a comparison between the 55 and 62 gr factory loads yet.

Sent the 55gr rounds downrange first and was mildly surprised. They grouped at 3 inches as compared to 6.5 on the first test. From here I think that playing with the powder charge might close that up a bit.

Time for the 65 grain beauties.. them dudes went ape s--t CRAZY!!

Lit off the first one and it hit 5 inches left and 3 inches low- just did nick the target. Ok, I could have pulled that one, tried the second one - didn't see no hole - grrr. Ran a dowel down the barrel just to make sure that it came out which it did. Looked for the hole again and found it about a foot high. Third one hit 8 inches high and to the right, Fourth one hit high and to the left. Fifth one was a FTF - twice - so the bullet got pulled and the case will be used for the next round of tests.

I managed to dig one of the bullets out of the old cooler that I have packed full of dirt and it pretty much disintegrated. All that was left was about a third of the lead and just bits and pieces of the jacket.

Overall fairly pleased with the imporvement of the 55gr performance though.

Need more testing

I have added pics for these--

Since my last post I added a riser to the DTI flat top. I made a new point forming die, a new punch for the final sizing die, and polished out the final sizing die to .224. Made up some 55 grainers without lead tips and some 65 grainers without lead tips. The runout at the tip was all but eliminated so I went ahead and loaded up 5 each over the same charge of 24gr of H355.

Got out this morning and sighted in the scope again using factory 55 gr hp ammo which resulted in a 1 inch group. Not exceptional but these progressive lens im my glasses give me hell. I have not done a comparison between the 55 and 62 gr factory loads yet.

Sent the 55gr rounds downrange first and was mildly surprised. They grouped at 3 inches as compared to 6.5 on the first test. From here I think that playing with the powder charge might close that up a bit.

Time for the 65 grain beauties.. them dudes went ape s--t CRAZY!!

Lit off the first one and it hit 5 inches left and 3 inches low- just did nick the target. Ok, I could have pulled that one, tried the second one - didn't see no hole - grrr. Ran a dowel down the barrel just to make sure that it came out which it did. Looked for the hole again and found it about a foot high. Third one hit 8 inches high and to the right, Fourth one hit high and to the left. Fifth one was a FTF - twice - so the bullet got pulled and the case will be used for the next round of tests.

I managed to dig one of the bullets out of the old cooler that I have packed full of dirt and it pretty much disintegrated. All that was left was about a third of the lead and just bits and pieces of the jacket.

Overall fairly pleased with the imporvement of the 55gr performance though.

Need more testing

Last edited by eagle60 on Sat Sep 10, 2011 1:21 pm; edited 1 time in total

eagle60- Member

- Posts : 971

Join date : 2011-01-02

Location : East Central MS

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

one moa is purdy darned good for a rimfire jacketed bullet dont think you can beat that.

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 65

Location : West Plains, Mo. , St. Louis ,Mo.

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

I wish I could help you but I'm no swager myself. Like others have already stated............at least you are making forward progress "Literally" and to start with nothing and put some bullets in a piece of paper deserves a pat on the back. Great Job!

Never be afraid to fail because that notion will stop you in your tracks before you even get started. In your case I would say you hit a home run because you actually have holes in paper, that's what I would call a success! Now you just need to tweak your process a little bit and tighten those groups up, hell your half way there man!

Never be afraid to fail because that notion will stop you in your tracks before you even get started. In your case I would say you hit a home run because you actually have holes in paper, that's what I would call a success! Now you just need to tweak your process a little bit and tighten those groups up, hell your half way there man!

Mohunter- Store Front Owner

- Posts : 944

Join date : 2010-10-18

Age : 56

Location : Missouri

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

I can be pretty stupid sometimes LOL I see it was the factory that you got the 1 moa with. I have Dies made by Richard Corbin and using 22 rim fires for jackets i have not gotten very good results. Great for making pinking bullets and a Coyote is big enough that a 3 moa round will dispatch it handily but I think you have a pretty good thing going on there.Reload3006 wrote:one moa is purdy darned good for a rimfire jacketed bullet dont think you can beat that.

I still am surprised though by the rate of twist of your bore and the weight of your bullets. I should love heavy bullets. That seems a bit confusing to me. but results are results.

Reload3006- Member

- Posts : 1761

Join date : 2010-11-19

Age : 65

Location : West Plains, Mo. , St. Louis ,Mo.

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Mo, thanks for the thumbs up! It seems that I have to find all of the 200 ways NOT to do something before I can get some results LOL! It has actually came out a little better than I ever expected but still want to do some tweaking "just to see what it can do"  But, all in all there is a lot of satisfaction in getting as far a I have.

But, all in all there is a lot of satisfaction in getting as far a I have.

No problem Reload - I kind of thought that was what happened I have my share of them to --

I have my share of them to --

I am confused about the heaver bullets to. I haven't done an actual measurement of the twist rate but was going by what it had in the catalog. Almost every one they make is either 1in7 or 1in9. Either way, I am surprised at the extreme difference in the groups. I am also surprised by you not getting good results with the rc dies. Maybe there is s limit to what the 22lr jacketed bullets will do ?

No problem Reload - I kind of thought that was what happened

I am confused about the heaver bullets to. I haven't done an actual measurement of the twist rate but was going by what it had in the catalog. Almost every one they make is either 1in7 or 1in9. Either way, I am surprised at the extreme difference in the groups. I am also surprised by you not getting good results with the rc dies. Maybe there is s limit to what the 22lr jacketed bullets will do ?

eagle60- Member

- Posts : 971

Join date : 2011-01-02

Location : East Central MS

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

What powder and charge are you using for the 65gr bullets? where does your charge sit between min and max? If you are at the min end of the spectrum...they might do better with a little more velocity. It is also possible they might do better at a slower speed if you have a stiff charge already. I notice your 55gr are charged with 24gr...is that also what you charged the 65's with?

My 60's weight bullets are usually at least 1gr less than that of my 50's weight bullets....sometimes even less.

I just looked over Hodgdon's data for H335. 24gr would be near max on a 65gr bullet. Try backing it off to around 22-23gr and retest. Sometimes slower is better in fast twist rate barrels....

My 60's weight bullets are usually at least 1gr less than that of my 50's weight bullets....sometimes even less.

I just looked over Hodgdon's data for H335. 24gr would be near max on a 65gr bullet. Try backing it off to around 22-23gr and retest. Sometimes slower is better in fast twist rate barrels....

hawcer- Mod

- Posts : 1896

Join date : 2010-11-04

Age : 53

Re: Home made 22lr to 223 bullets

Re: Home made 22lr to 223 bullets

Yep, I used 24gr of H335 on both the 55 and 65 grain bullets. I knew it would not be optimal for either one but would get me in the ball park. I agree with your thinking and it sounds like that would be a good basis for the next round of tests. I'm going to have to find some more of the (stinger type) longer jackets though, I only had 7 if them and messed 2 up . I had actually tried making some copper tubing jackets but it is going to take a whole different approach than the 22lr jackets. It is a lot harder to get the jackets off the punch. Could the punches for copper jackets have a little taper to them? It seems like it would make it easier to get the jacket off the punch and would make a jacket that is a little thinner towards the tip. I finally got one pried off the punch and the base flattened out but it was too beat up to use lol!

eagle60- Member

- Posts : 971

Join date : 2011-01-02

Location : East Central MS

Similar topics

Similar topics» Practice Home Made De rim Die..

» Anybody make k-spinners? Home-made?

» My home made 45 cal swaging dies.

» My half baked idea for .22LR to .223

» Using a Lee .224 sizer die to make jackets out of 22lr

» Anybody make k-spinners? Home-made?

» My home made 45 cal swaging dies.

» My half baked idea for .22LR to .223

» Using a Lee .224 sizer die to make jackets out of 22lr

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum